Products

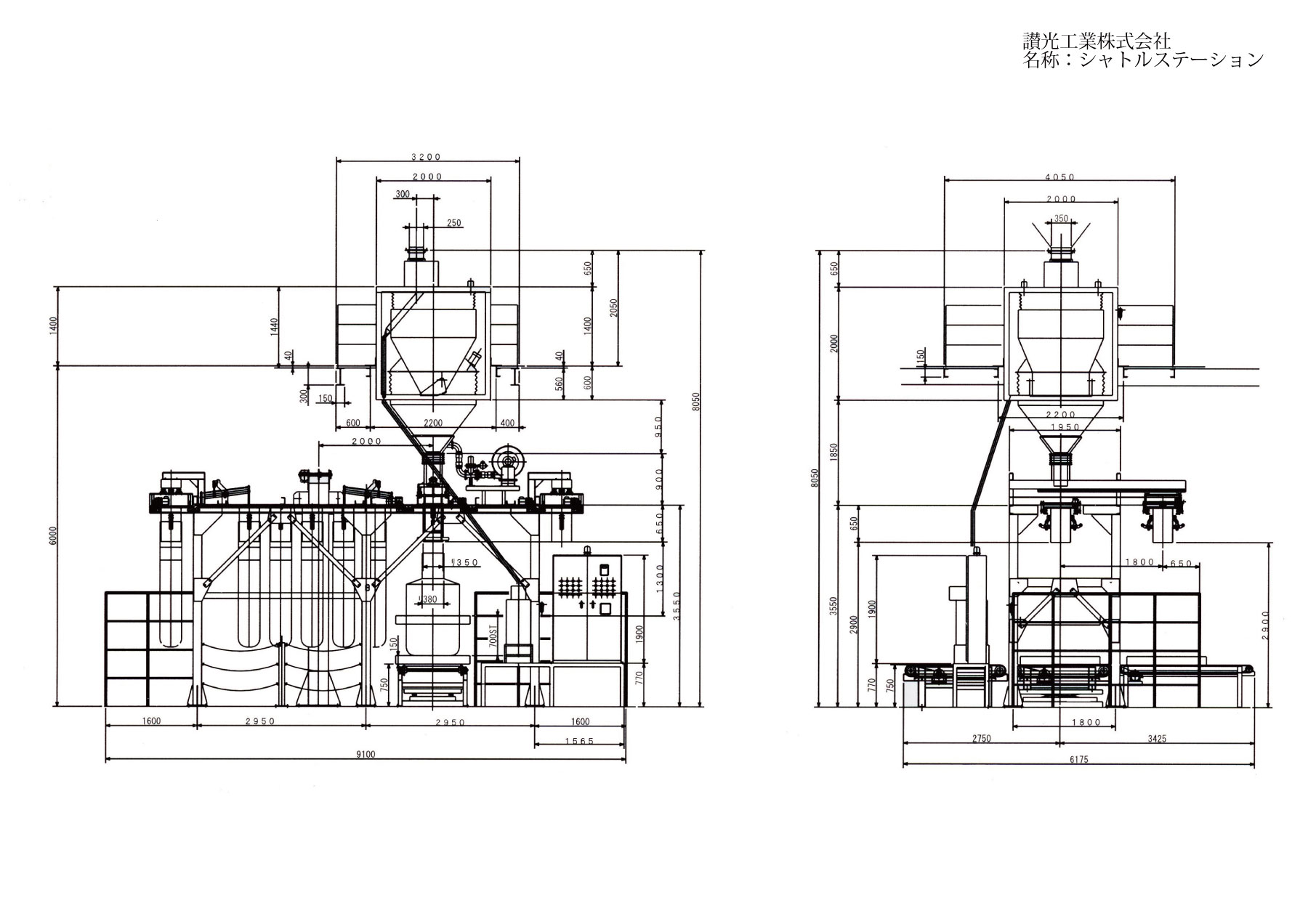

Shuttle Station

If the flexible container bag is attached to the mounting port called a shuttle in advance, the flexible container bag movement, bag inflation, filling, bag removal, and carrying out are all automatically performed, and the operator only needs to close the bag at the end. One worker will easily handle installation of bags where previously 2 workers were required. This automation will result in a significantly improved efficiency level than before.

Main Specifications

SSS-N01: net weight type(weighing line 1place)

Business Type or Packings

Features

・One worker will easily handle installation of bags where previously 2 workers were required.

・There is no need to remove the bag or do heavy labor such as carrying out .

・The bag inflation device and bias prevention guide can be used to achieve the most suitable shipping appearance.

・This automation will result in a significantly improved efficiency level than before.

Various parts and options

・Pallet magazine

・Conveyor extension

Back to list

Back to list